Stockout is when customers can’t find the product they want at their desired store or find the product in an unsuitable condition (damaged or out of date). In the retail industry, stockouts are defined through the eyes of customers. Therefore, an essential question for retailers is the size of the lost sales from stockouts. Conversely, if you fix this problem completely, how much will your sales increase? This article will explain “What is a stock out?” and how retailers can prevent it.

What is a stockout?

Stockout or out-of-stock (OOS) is a condition in which the inventory of a particular product is depleted. For a retail store, stockout is a term for a product that is not available at this store shelf but may be available in another location in the supply chain. Therefore, ensuring the right product hits the shelf at the right time for optimal order fulfillment is crucial as it increases the chances of sales and delivers the best customer experience. As a Pareto principle, retailers should eliminate 20% stockouts of the items that make up 80% of total sales to impact profits significantly.

Stockouts definition is most evident in the FMCG sector. For example, a customer walks into a grocery store to find his Evian brand, but it’s out of stock. This customer will consider choosing another brand as an alternative or delaying the purchase. However, none of the options benefited Evian’s sales. Thus, retailers need to do everything they can to avoid inventory stockout. Instead of reacting, actively think about it.

What causes a stockout?

Inefficient supply chains or store operations are the leading causes of stockouts. Here are the 3 most common reasons for the out-of-stock situation.

Incorrect demand forecast

Most stockouts are due to a lack of inventory forecasting system or the absence of historical inventory, sales, and sales data for reference — inaccurate inventory data due to shipment deviations, lost products, returns, or stolen items. In addition, the factors that influence forecast accuracy are promotions, seasonality, and your economic environment. Some retailers admit that they don’t have a stockout indicator in their organization to drive better results.

Inefficient inventory management process

Incorrect data can be another cause of stockout. For example, if you don’t include damaged or stolen products in your inventory management records, sales-based ordering systems will continue to think those items are still on the shelf. As a result, additional orders are not created on time or until adjustments are made.

Stockouts are also a sign of human error; you may need to consider training your staff to set up warehouse inventory to track inventory more efficiently and make replenishments at the right time.

Shortage of working capital

In addition, an unavoidable subjective cause is the shortage of working capital of small-scale retailers. It can stem from poor cash flow management and capital turnover. From there, it limits the order value or delays additional orders.

What are stockout costs?

Stockout costs are the costs for retailers due to out-of-stock items, including the following 4 components:

Inventory carrying cost

Suppose that you’re running an end-of-season sale; stockouts reduce the impact of discount promotions. Moreover, when the goods reach the store, customers may have been discouraged and won’t buy again. It can result in higher inventory carrying costs such as dead or obsolete inventory that you can no longer sell due to being out of season.

Order processing cost

Suppose that your customer doesn’t want to wait for the out-of-stock item back in stock; they may re-order it. As a result, your customer service will modify the order to create a new matching delivery date. In addition, there may be additional shipping charges if stockouts are part of a larger delivery, where a later order will require special shipping.

Compensation cost

There is also the cost of minimizing customer dissatisfaction by offering incentives to prevent negative reviews on social media. As a result, the retailer may have to provide customers free shipping or a discount to compensate for the inconvenience caused by stockouts.

Lost-customer cost

Losing customers to stockouts is the highest cost to a retailer. If the customer is a large buyer, the costs can be very high and put you in financial trouble. In addition, there is the cost of finding new customers, which is usually 3 times higher than nurturing old customers.

How stockouts can hurt your business?

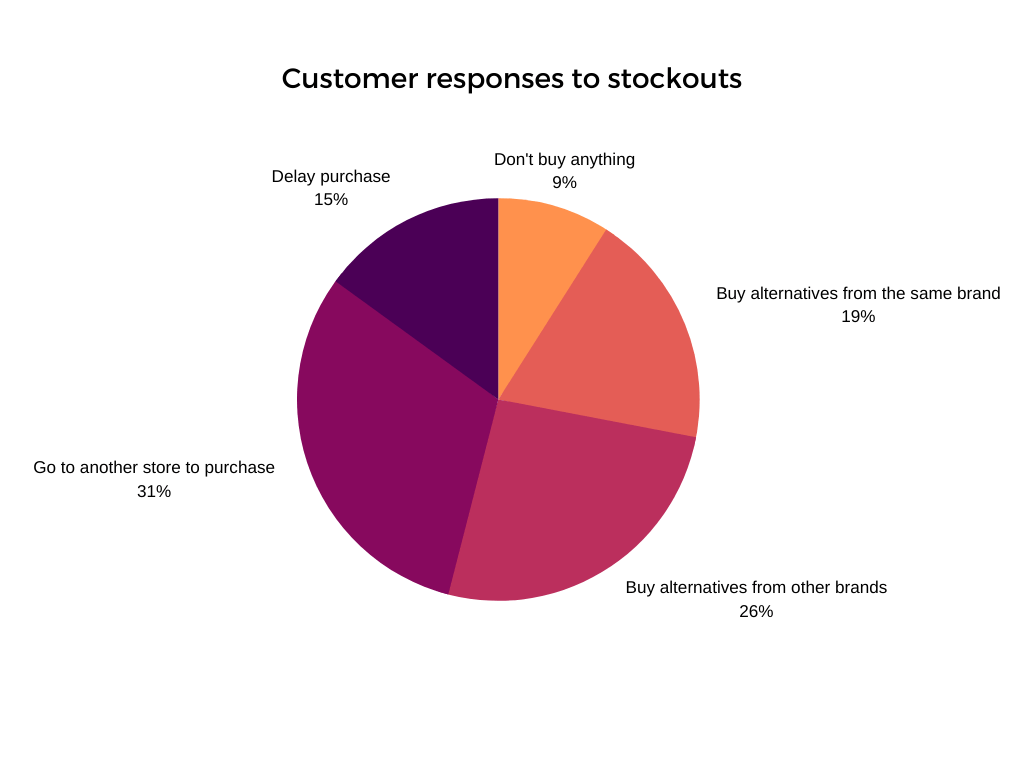

Stockout can hurt retailers, their customers, and suppliers. However, the approach to answering this question is from the customer’s point of view. According to a survey of what customers would do if their favorite product were out of stock, retailers will lose money when customers don’t buy anything (9%), buy from another brand (26%), and purchase alternatives or smaller sizes of the same brand (19%). Thus, your total sales loss rate can be up to 54%.

In the fiercely competitive retail market, being able to retain existing loyal customers is extremely important. But, unfortunately, the losses caused by stockouts are huge. For that, we’ll suggest ways you can reduce inventory stockout for your retail business in the next section.

5 ways to handle stockouts in store

Even the most diligent retailers run out of popular products to sell at times. Let’s look at 5 ways your staff can handle this situation and create a better shopping experience.

Offer related or replacement item

Sometimes the customer is willing to buy a substitution product if there’s a stockout. For example, if the dress they want doesn’t have the correct size, your sales staff can recommend another item in a similar color or style.

For this method to be successful, your employees need to know the customer and why they want to buy the original item. Effective consultation makes the customer feel your staff genuinely care about them instead of just trying to sell products.

A retail POS system that provides customer information — address, purchase history, preferences — can help your employees understand the customer and deliver more personalized consultation.

Request an inventory transfer for later pickup

If your staff can get the items transferred quickly from a nearby store or warehouse, they can suggest the customer return later to pick up their order.

This solution to stockout has 6 key steps:

- The customer requests an item that’s out of stock in the store.

- Your staff checks the inventory of nearby stores or warehouses to see if the item’s available.

- If there’s stock for the item, the staff informs the customer when they can pick up their purchase. Your cashier can create an order in the POS system immediately or wait until the customer picks up the product.

- Your staff makes an inventory transfer request to get the item delivered to the store. Alternatively, they can also go to the other store to get the product directly.

- Your staff contacts the customer to let them know the product is ready for pickup.

- The customer returns to pick up the item and complete the sales.

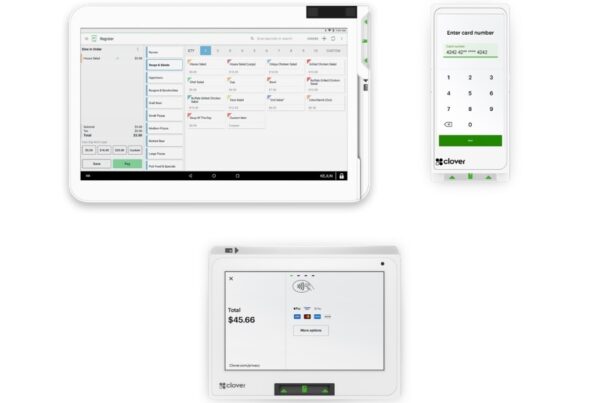

Your POS should make this process easy and accurate for your staff. Your retail system should have features such as product lookup, inventory transfer and adjustment, and creating shipment.

Create the order for another store and ship to the customer

Retailers can use this option when the items are in stock in another store and the customer isn’t in a hurry to receive the products.

- Your cashier checks your inventory system to identify the store with enough stock.

- The staff creates an order for the other store with the customer’s shipping address.

- The employee from the other store checks the order on the POS system and ships the items to the customer.

- The customer receives the product from the other store.

For this process to work, your retail system needs to support creating orders for another location. A centralized POS system will help connect all the registers and keep sales and inventory data correct.

Create and ship the order from multiple stores

Another way to handle stockout situations is to ship from multiple locations at the same time. Here’s the process:

- Your cashier selects the locations and quantity to ship from each store.

- The staff chooses the shipping method for each shop and completes the checkout.

- Your POS system creates multiple orders corresponding to the selected stores.

- The employees from these locations prepare for fulfillment based on the sales order details.

For more details, check out our customized solution for endless aisle.

Create backorder and restock items

Sometimes the customer can wait until you restock items from the suppliers. If this is the case, you can create a backorder for the out-of-stock items, then purchase more from the suppliers to fulfill the order.

Learn more about this method in our article on backorder management.

How to prevent stockouts

Thankfully, you can prevent most of the underlying causes of stockouts with effective retail store operation procedures. You should strengthen your retail activities and practice effective supply chains to minimize the risk of stockouts. The most straightforward approach to avoid stockout costs is to unravel the link between out-of-stock prevention practices and on-shelf availability (OSA).

Regular stocktake

Stocktake is an essential part of inventory management to ensure you always have the right amount of items for sale and identify potential inventory issues. It’s the process of manually verifying the actual quantity and quality of products in your retail inventory. From there, you can decide how to move inventory and how much to buy from suppliers. As a result, you can maintain the item’s freshness or reduce inventory stockout on any occasion. Moreover, regularly monitor your reports and adjust your delivery cycles based on historical inventory data and seasonal fluctuations.

Timely replenishment on shelves

SME retailers should arm themselves with physical inventory management software to avoid stockouts from all of their retail locations. In addition to maintaining inventory levels, you can also monitor on-shelf availability. Then, switch to an automated in-store ordering system and share sales and inventory data with your partners. From there, you will get more accurate demand forecast reports. In addition, you can work with various partners to bring products to the shelves in total stock on time and in replenishment quantities.

Supply chain optimization

You might consider using a radio frequency identification (RFID) system for supply chain transparency for more sophisticated retail businesses and reduce stockout costs. This type of technology uses a chip in the item’s packaging to track the item’s movement at the individual product level throughout your supply chain, including retailers, distributors, and manufacturers.

In addition, you need to determine which product SKUs are in high demand now and in the long term so that you don’t have to compete with other retailers at the last minute to get enough products.

Related questions

How do you calculate a stockout?

After understanding “What is a stock out?”, you may wonder how to calculate it. You may use one of the 6 methods listed below. However, each method has its limitations, leading to long-running debates within retail organizations about the extent of the stockouts problem and who is responsible.

- Store staff internal review (How many holes are left on the shelves?)

- Independent third-party testing (Is the product on the shelf?)

- Annual inventory record (How many items are zeroed in the inventory records?)

- Service level of the store (Do customers who buy online receive their products in-store?)

- Customer surveys at checkout (Did shoppers get everything they wanted on this visit?)

- Post-purchase customer surveys (Did customers get everything they wanted on their last visit?)

How do you avoid stock out costs?

With retail, you should take a strict customer-centric approach to avoid stockout costs. To start, you can implement better measurement and increase inventory management attention. From there, use 5 innovative levers, including:

- Improved replenishment systems (forecast and schedule)

- Simplified business strategy (scope and layout)

- Increased inventory levels accuracy

- Better promotion management

- Automated in-store ordering systems

What is the probability of a stockout?

The average probability of a stockout in the global market is 8.3%. In other words, more simply, in a cart of 100 items, customers expect only 8 of the items to be out of stock, and the other 92 are available for purchase. However, this number can vary depending on the following factors:

- Category, size, and type of store (stores are less likely to be out of stock than hypermarkets)

- Day of the week (stockouts occur more frequently on weekends)

- Promotional items (promotional items are up to 75% more out of stock than non-promotional items)

Final thoughts

We hope the article helped you understand “What are stockouts?” Most customers don’t want to hear “Sorry, we’re out of stock”. Moreover, stockouts affect sales, brand value, and customer trust. As such, you should consider investing in the right tools to enhance inventory management, partner with distributors and manufacturers, and adequately train employees to reduce the negative impacts of stockout costs.

If you’re looking to reduce stockouts and streamline your operations, you can get started by booking a free consultation with Magestore. Together we can build a solution that fits your business.