Retail inventory management can directly affect your profits. We’ve spent over 11 years helping retailers and have seen firsthand how good inventory control can turn struggling stores into successful ones. But we’ve also watched businesses lose money and customers because of poor inventory practices.

Let us walk you through everything you need to know:

- The basics of retail inventory management and why you can’t ignore it

- Six types of inventory you should track in your store

- Simple ways to manage your stock, from ordering the right amounts to working with vendors

- Numbers that matter when making inventory decisions

- Real solutions to problems you might face

- Four tested tips for inventory management in retail stores you can use right now

Get your insight below!

- What is inventory management in retail?

- How does retail inventory management work?

- Retail inventory management methods for retailers

- Top 3 inventory accounting techniques

- 13 must-known retail inventory management metrics

- 5 inventory analysis and forecasting methods

- Top 5 inventory audit methods

- 5 common challenges of retail inventory management

- 4 best practices for retail inventory management

- What is the future of inventory management in retail?

- How can Magestore help?

What is inventory management in retail?

Retail inventory management is how stores track their products. It provides a system that can always tell what is on the shelves. You can think of it as a continuous process — when new items arrive at your store, you add them to your count. When customers buy things, you subtract them. The idea is to stock only the right amount of products that will sell without overbuying or underbuying.

Good inventory management ensures a retail shop has what customers want at the right time. You don’t wish to have excess stock lying around because it wastes money and space. On the other hand, you don’t like to run out of products either. Running out means losing sales and having unhappy customers walk out empty-handed.

For instance, you own a small convenience store and observe data from inventory management that ice cream sells well on hot summer days, but hardly anyone buys it in winter. This data tells you to keep your freezer stocked with various flavors during the summer. In the winter, just a few basics are enough.

Over time, you begin to see which flavors your customers prefer via reports of the inventory system. Chocolate may sell out quickly, while mint ice cream sits in the freezer. All these patterns give you better insight to plan your orders. Next summer, you’ll know to stock up on chocolate and reduce mint flavors. As a result, you can keep your customers happy without having any money frozen in unsold ice cream.

9 Reasons why inventory management is important in retail

Below are some vital aspects that highlight the importance of inventory management in retail:

1. Improve cash flow: Proper inventory management boosts your cash flow and profits. You will not lose money on products that stagnate on shelves and incur lower storage costs.

2. Optimize perishable and seasonal product management: Timing is essential when selling perishable items. Under good management, you sell these products before they spoil, thus avoiding the waste of expired products.

3. Anticipate market trends: Some items, like last season’s fashion or outdated technology, don’t expire but can become irrelevant. But with smart inventory tracking, retailers can avoid getting stuck with items nobody wants anymore.

4. Increase stock accuracy: Proper inventory management prevents overselling or faux availability of items.

5. Enhance customer satisfaction: Customers who find what they want in your store are likelier to return. Proper replenishment of goods helps keep them happy as well as loyal.

6. Enable seamless omnichannel retailing: Shoppers today demand a frictionless shopping experience regardless of the channel. Good inventory management makes it possible by keeping your stock levels between the brick-and-mortar shop and digital platforms. Thus, you can confidently offer your customers hassle-free options like buy-online-pickup-in-store (BOPIS). With real-time inventory updates across all sales channels, you will never disappoint a customer with an out-of-stock item they saw online.

7. Leverage data analytics for better decisions: Modern retail inventory management systems show you which products sell best during different seasons so you can stock up at the right time.

Need to know when to reorder popular items? It will proactively notify you before running low on stocks. Moreover, it will indicate which products are selling fast and which are not moving off the shelves quickly enough. No more purchased decisions based on intuition — today, you make acquisition choices based on factual data.

8. Streamline daily operations: When your inventory is well-organized, everything runs better. Your employees should be able to locate items quickly, which will help them process orders faster. You will also spend less time and money on storage.

9. Stay competitive: Effective inventory management enables businesses to offer competitive prices, achieve reasonable profits, and adapt quickly to changing market trends or customer preferences.

6 main types of retail inventory

There are six fundamental types of retail inventory that a business needs to manage.

1. Finished goods: Products are available for immediate sale to customers.

Example: Clothes hanging on the rack, boxed-up electronics, and furniture ready to be sold.

2. Raw materials: These are the basic stuff you need to create your final products.

Example: A furniture maker needs wood and metal, while a bakery needs flour, sugar, and other ingredients.

3. Work-in-progress or work-in-process (WIP): Such items are unfinished. You initiate the work on them, but they require more time or labor before they can hit the market.

Example: It could be phones under repair in an electronics shop, unfinished jewelry, or garments altered to fit a customer.

4. MRO (Maintenance, Repair, and Operations) goods: These are things you need to run your business so you don’t sell them to customers.

Example: Cleaning supplies, office materials, and maintenance tools

5. Dead stock: This is inventory that just won’t sell. If something sits on your shelf for 6-12 months without selling, it’s probably dead stock.

Example: Last year’s fashion or outdated technology.

6. Safety stock: This stock is your backup inventory to protect your retail stores against uncertainties in supply chain processes like delayed shipments or sudden demand spikes.

Example: A clothing store sells 50 jackets weekly, with a 2-week supplier lead time. To prevent stockouts during demand spikes or delays, they keep 20 extra jackets as safety stock, ensuring uninterrupted sales.

Read more: What is the 80/20 inventory rule? 6 tips to implement it efficiently

How does retail inventory management work?

Every retail shop requires some sort of inventory management system. The purpose is to know what one has, where everything is located, and when to reorder. If you have too little stock, you have empty shelves and unhappy customers. On the other hand, stocking too many products is not wise either because it costs money and takes up valuable space

Let’s break down how inventory management for retail works:

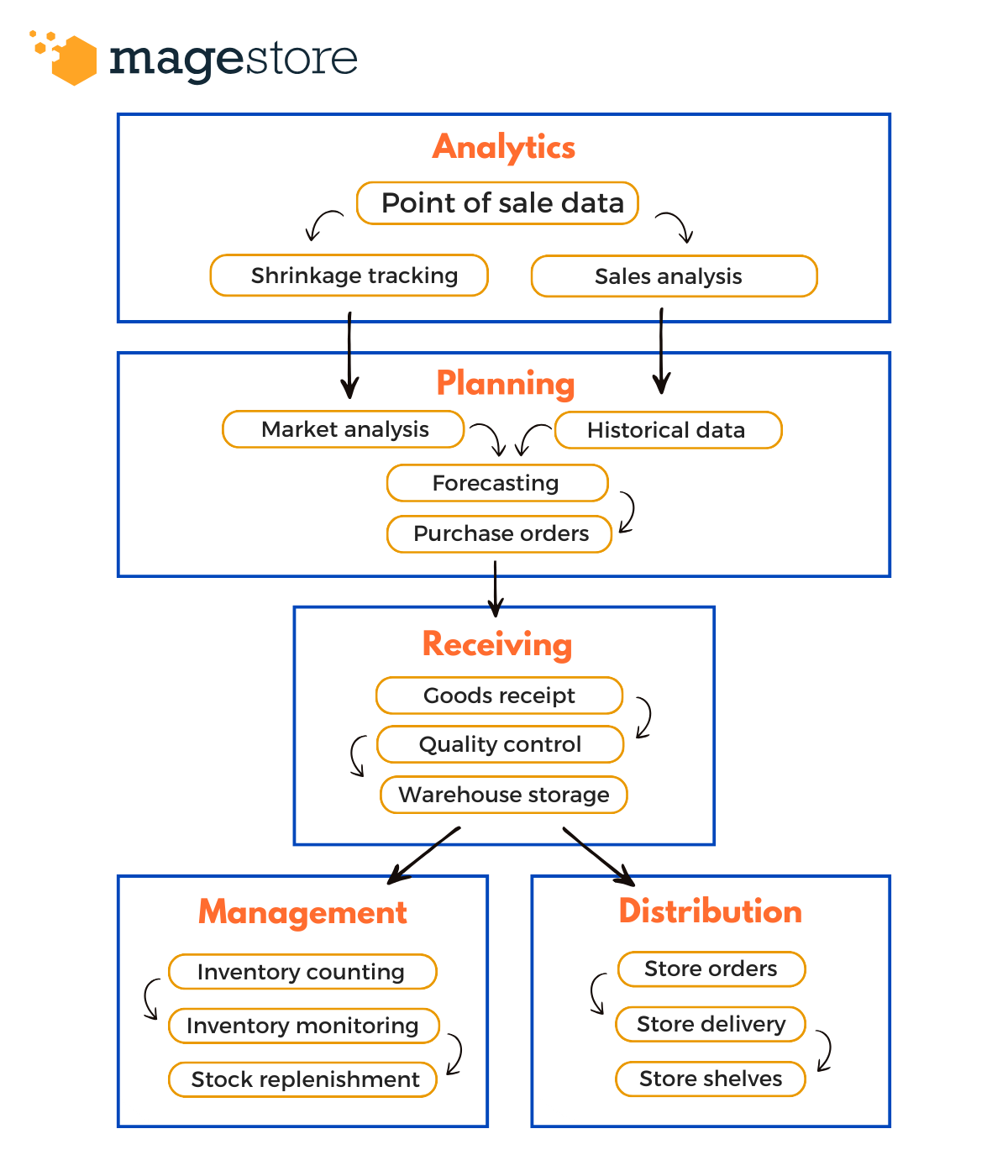

Stage 1: Planning phase

It begins with a detailed plan. The store managers use the historical sales data and monitor the market trends to determine what their customers need next. In planning inventory requirements, they consider everything from holiday rushes to seasonal changes. Based on this analysis, they:

- Calculate the required quantities for each product

- Create purchase orders specifying items, quantities, and delivery dates

- Submit orders to approved suppliers

- Keep records of all placed orders for later verification

Stage 2: Receiving operations

When new shipments arrive, employees count the quantities, check the quality, verify the received items and quantities against purchase orders, and then store the items in the warehouse. Such attention prevents problems later on and also keeps the inventory system accurate.

Stage 3: Active management

The actual work is in the day-to-day management. Modern shops use sophisticated systems to track inventories — almost like a wise shopping list that updates itself. Regular counts and automated reorder systems help ensure that stocks are kept at ideal levels without incurring excessive costs in surplus inventory.

Stage 4: Distribution process

Stocking the shelf from the warehouse is essential. The store manager closely coordinates with the warehouse personnel to schedule deliveries and manage display space. This prevents empty shelves as well as overstuffed stockrooms and makes products accessible to customers.

Stage 5: Analytics and optimization

In modern retail, data drives decisions. Beyond recording transactions, analytics tools allow managers to dig deeper into inventory performance. Point-of-sale (POS) systems and inventory management software provide insights that allow managers to continuously refine their inventory strategies, ensuring the right products are available in the right quantities while minimizing costs.

Explore solution: Learn more about the best POS system for Magento for your business

Retail inventory management methods for retailers

Depending on your brand’s niche and sales volume, it may rely on specific management strategies to ensure timely delivery of goods and a stable inventory management cycle.

Here are some of the most common methods used when brands must manage inventory.

You may think of these techniques as tools in a toolbox. Each serves a different purpose, and combining them strategically helps businesses balance cost, efficiency, and responsiveness:

Inventory ordering techniques

1. Economic Order Quantity (EOQ)

Economic Order Quantity (EOQ) helps businesses know how much inventory to order at once. When you order too much, you waste money on storage. When you order too little, you order too often and risk running out. EOQ finds the sweet spot that saves you the most money.

While this formula was created back in 1913 by Ford Harris, it’s still widely used today with one primary assumption: your demand and costs stay the same over time.

The formula is: EOQ = √(2DS/H) Where

|

Key limitations:

- Not tell you when to reorder

- Less accurate for perishable items

- Can’t wholly prevent stockouts

- Assume constant demand and costs

For example, a coffee shop orders coffee beans:

- Annual demand (D): 5,000 bags

- Order cost (S): $50 per order (shipping + handling)

- Holding cost (H): $10 per bag per year (storage + risk of spoilage)

=> EOQ = √(2 × 5,000 × 50 ÷ 10) = √50,000 = 224 bags — This means the coffee shop should order 224 bags per order to minimize total costs.

2. Minimum order quantity (MOQ)

Think of Minimum order quantity (MOQ) as the “minimum purchase rule.” Suppliers won’t sell you tiny amounts. They need you to buy in bulk — like ordering at least 500 T-shirts instead of just one.

This creates a chain of factories → wholesalers → stores → customers, with smaller order sizes at each step.

For example, a pen supplier has a Minimum Order Quantity (MOQ) of 50 pens.

- The supplier will not accept the order if a customer wants to order 30 pens.

- The supplier will accept the order if a customer orders 50 pens or more.

3. Just-in-Time (JIT)

Just-in-time (JIT) means ordering supplies exactly when you need them for production – no earlier, no later. This inventory strategy helps companies become more efficient and reduce waste by allowing them to receive goods only when they need them in production. Of course, it lowers inventory costs. The trick is that you need to be really good at predicting when you’ll need materials.

For example, Starbucks orders milk deliveries to arrive just before they run out. They track how many lattes they sell daily and time their orders so fresh milk arrives right when needed, avoiding waste from spoilage.

4. Par Level Ordering

PAR-level inventory management is based on identifying when stock has fallen below a pre-set level.

Simply put, you set a minimum amount you always want in stock. When inventory drops below this level, it’s time to order more. The par level includes enough extra stock to handle surprise increases in demand.

PAR Level = (Average daily usage × Days between deliveries) + Safety stock |

For example:

- Daily usage = 50 bottles /7 days ≈ 7.14 bottles per day

- Days between deliveries = 7 days/2 deliveries per week = 3.5 days

- Safety stock = 10 bottles

=> PAR Level = (7.14 × 3.5) + 10 ≈ 35 bottles. You should maintain a par level of 35. Whenever the stock falls below this level, you must order more water to avoid running out before the next delivery.

5. ABC inventory analysis

ABC analysis is a retail inventory management formula that helps you sort your products by importance to your retail stores. Take an example of how we organize the closet – some clothes we wear all the time, others occasionally, and some rarely.

Products are grouped into classes:

- A items are your stars (most important stock-keeping units (SKUs), based on either sales volume or profitability )

- B items are your steady performers

- C items are your least critical products

Some businesses use more categories, going up to F for even finer sorting.

6. Vendor-Managed Inventory (VMI)

VMI is an inventory management approach wherein a supplier or vendor controls and maintains the inventory, even when the inventory resides in a retailer’s warehouse.

In this case, the supplier manages your inventory. For example, Walmart has Coca-Cola manage its soda inventory – Coke tracks the store’s stock levels and automatically ships more products when needed. They use special software to keep track of everything and thus ensure Walmart never runs out or has too much in stock.

12 common inventory fulfillment methods

1. In-house fulfillment

Running in-house fulfillment means taking care of everything to fulfill yourself. You handle all the moving parts:

- Receiving products and storing them

- Keeping track of what’s in stock

- Taking care of incoming orders

- Finding and packing products for shipping

- Getting orders out the door

- Watching where shipments are

- Dealing with returns

- Helping customers with questions

You can run this operation from wherever it makes sense for your business. Some start in their garage, while others need a proper warehouse. It depends on how many orders you’re handling.

Best for: Smaller companies want to handle everything themselves. This method works well when special products need extra care.

2. Third-party fulfillment

Third-party fulfillment, also known as the 3rd-party logistics (3PL) model, entails outsourcing all order fulfillment activities to an order fulfillment vendor or other 3rd-party. You still own the products, but someone else stores and ships them for you. This works great for online sellers who don’t want the hassle of running a warehouse.

Best for: Growing businesses don’t want to deal with shipping and storage. You can focus on selling while someone else handles the shipping work.

3. Drop-shipping

Dropshipping is a type of order fulfillment in which an eCommerce business outsources the procuring, storing, and shipping of products to a 3rd party, typically a supplier.

This fulfillment model typically attracts entrepreneurs focused on efficiency and low overhead costs. Still, it can come with a price — you have less control over how your customers get their orders.

Best for: Retailers just starting their business who don’t want to buy inventory first. They can use dropshipping to test selling products without spending much money.

4. Hybrid fulfillment

A hybrid model combines two or more of the three models above. For example, you might ship your bestsellers yourself but use drop-shipping for bulky items. During busy seasons like holidays, you could bring in a 3rd-party logistics business to handle the extra orders.

Best for: Retailers sell different kinds of products. You might ship some things yourself and let others handle the rest.

5. Consignment

Have you ever seen local honey being sold at a grocery store? That’s consignment. You put your products in someone else’s store but still own them. The store only pays you after they sell your items. They’re just letting you use their shelf space for a sale cut.

Best for: Small brands just starting, artists, and anyone selling expensive items who can’t afford to make them all upfront.

6. Cross-docking

Cross-docking is a quick way to move products. Items are taken from incoming trucks and loaded straight onto outgoing trucks. There’s no need to store them in a warehouse.

For example, at Walmart, a truck brings fresh vegetables at 6 AM. The staff quickly sorts them and puts them onto smaller trucks. By 8 AM, these trucks are already on their way to local stores.

Best for: Fresh food, seasonal items, or anything that needs to move quickly.

7. Picking and packing

Picking and Packing is about getting items ready for shipping. First, workers find and collect the ordered items. Then, they pack them safely for delivery.

For example, say someone orders makeup from an online store. Amazon workers walk around with carts, check their phones for what to grab next, and pack boxes.

Best for: Any store that ships lots of different items every day.

8. Marketplace fulfillment

Marketplace fulfillment is a fulfillment service where a platform handles product storage, shipping, and delivery for 3rd-party sellers who list items on their marketplace.

For example, a small jewelry maker sells their products on Amazon and uses Fulfillment by Amazon (FBA). They send their products to Amazon’s warehouse. After that, Amazon handles everything else – storage, packing, shipping, and returns.

Best for: Small sellers who don’t want the headache of shipping stuff themselves.

9. Just-in-time fulfillment

Just-in-time fulfillment means only ordering products when they’re needed. So, retailers can save money on storage costs.

For example, Zara doesn’t keep lots of clothes in their stores. They get new deliveries every few days based on what people are buying.

Best for: Retail stores sell trendy items like fashion or food. You only order what you need when you need it.

10. Dark store

Dark store is a store that looks like a regular store but isn’t open to shoppers. It’s only used to prepare online orders.

For example, Tesco has special stores in cities that customers can’t visit. Inside, workers collect groceries for online orders and prepare them for delivery.

Best for: Online grocery stores in busy cities. These stores can quickly pack and deliver orders to nearby customers.

11. Subscription fulfillment

Subscription fulfillment refers to sending products to customers regularly on a set schedule.

For example, Dollar Shave Club has special warehouses that send razors to customers every month, depending on their monthly plan.

Best for: People need regular food, beauty products, and household items.

12. Regional fulfillment hub

Multiple warehouses spread across different locations to speed up delivery.

For example, Target uses local stores as mini-warehouses to ship online orders faster to nearby customers.

Best for: Large businesses with nationwide customer bases who want to offer fast shipping.

Top 3 inventory accounting techniques

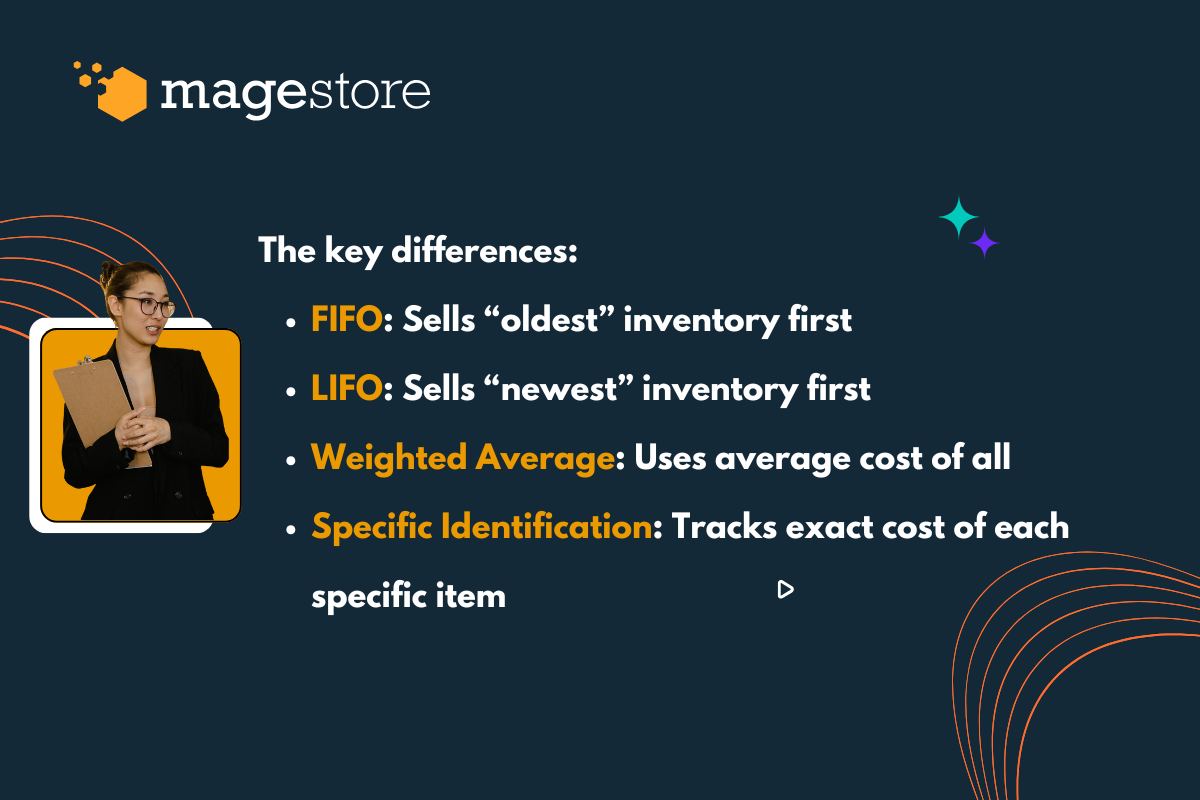

1. LIFO vs FIFO

Last in, first out (LIFO) inventory management assumes that the items purchased most recently are the ones sold first. If prices increase over time, then the inventory to be most recently purchased will also be the most costly. Accordingly, higher inventory costs would lead to lower profits and, thus, a lower taxable income. U.S. companies mainly use LIFO to pay less tax when prices rise, especially in industries like oil and metals.

On the sidelight: LIFO is only available in the United States (under US GAAP) but banned everywhere else (under IFRS). Why? Most companies sell their older stock first, not their newest items – think about grocery stores selling older milk before newer milk. And LIFO goes against this rule. This mismatch between LIFO accounting and actual business practice is why IFRS banned LIFO.

First in, first out (FIFO) is the method used to determine costs associated with selling goods, otherwise referred to as cost of goods sold (COGS). This means that the oldest inventory is sold first, which is particularly important in preventing spoilage. So, FIFO is ideal for businesses selling perishable goods: supermarkets, food stores, and restaurants.

LIFO vs FIFO example

A furniture store purchasing wooden chairs in three lots:

- January: 100 chairs at $50 each

- June: 100 chairs at $60 each

- December: 100 chairs at $70 each

If they sell 150 chairs in December:

Under LIFO: (You don’t touch the January chairs in this sale. The last inventory that came in December is the first to go out when selling)

- 100 chairs at $70 (newest batch) = $7,000

- 50 chairs at $60 (middle batch) = $3,000

=> Total COGS = $10,000

Under FIFO (First In, First Out):

- 100 chairs at $50 (oldest batch) = $5,000

- 50 chairs at $60 (middle batch) = $3,000

=> Total COGS = $8,000

2. Weighted Average Cost (WAC)

Weighted average cost is a method where companies calculate the average cost of their inventory by considering the cost and quantity of each purchase. Unlike FIFO, which sells the oldest items first, or LIFO, which sells the newest items first, WAC treats all inventory units as having the same average cost regardless of when they were purchased.

This “weighted” approach creates a single uniform cost for all items. The best use cases for this are when dealing with large quantities of similar items purchased at different prices.

Follow the WAC formula below to calculate the weighted average cost: WAC per unit = COGS/units available for sale Where

|

Weighted Average Cost Example

A clothing store has:

- Opening inventory: 200 shirts at $10 each = $2,000

- First purchase: 300 shirts at $12 each = $3,600

- Second purchase: 500 shirts at $15 each = $7,500

- Total cost = $13,100

- Total units = 1,000 shirts

=> WAC per unit = $13,100 divided by 1,000 = $13.10 per shirt

3. Specific Identification

Specific identification tracks each item in inventory individually. Instead of lumping like items, it follows each product from purchase to sale.

Unlike the FIFO and LIFO inventory assessment methods, which group items based on the purchase date, specific identification considers each item unique. You attach a tag to each product showing how much you paid for it, plus any extra costs you had.

This approach is most suited for big-ticket items like cars or furniture. It’s also helpful when you sell products with vast differences in features and price.

Specific Identification Example

A luxury car dealership buys three Mercedes:

- Car A: $80,000, dealer prep $2,000, shipping $3,000 => Total cost = $85,000

- Car B: $55,000, dealer prep $1,500, shipping $2,500 => Total cost = $59,000

- Car C: $40,000, dealer prep $1,000, shipping $2,000 => Total cost = $43,000

When you sell Car B, the exact cost of $59,000 is recorded as COGS, regardless of when the other cars were purchased or their costs.

13 must-known retail inventory management metrics

1. Inventory turnover: Refers to the rate of how many times inventory is sold and replaced over a specific period.

- Formula: Cost of Goods Sold/Average Inventory

- Healthy benchmark:

- Fashion retail: 4-6 times/year

- Supermarket: 12-14 times/year

- Electronics: 6-8 times/year

- Example: a boutique shop has yearly COGS of $2M and an average inventory of $400K → Inventory turnover = 2,000,000/400,000 = 5 times/year. So, with 5 turns per year, this boutique performs well within the fashion retail benchmark of 4-6 times/year.

2. Days Inventory Outstanding (DIO): Tell you the average number of days a company holds inventory in the warehouse before selling it.

- Formula: (Average Inventory × 365)/Cost of Goods Sold

- Healthy benchmark:

- Fashion: 60-90 days

- Supermarket: 25-30 days

- Electronics: 45-60 days

- Example: From the above case → DIO = (400,000 × 365)/2,000,000 = 73 days. This number falls well within the healthy benchmark range for fashion (60-90 days). But you can optimize this figure further since it sits in the middle range. Consider promoting any slower-moving items to help boost this number slightly.

3. Days Sales of Inventory (DSI): An alternative measure for DIO. This metric focuses on the days taken to turn inventory into sales.

Note:

– DIO is your best choice when looking at how money moves through a business and how much working cash they have. It’s beneficial when you’re putting together financial reports or comparing different types of companies.

– DSI works better when looking at how a business runs day-to-day. DSI is handy when you care more about how much inventory is left at the end of each period rather than the average amount.

- Formula: (Ending Inventory/Cost of Goods Sold) × 365

- Healthy benchmark: Similar to DIO benchmarks

- Example: Store has ending inventory of $380K and annual COGS of $2M → DSI = (380,000/2,000,000) × 365 = 69.35 days. The DSI of 69.35 days is also within the healthy range for fashion retail. This is slightly better than the DIO number above (73 days), suggesting that retailers are managing inventory levels well.

4. Stock-to-Sales Ratio: Measures the relationship between inventory levels and sales. Thus, it reflects efficiency in using inventory.

- Formula: Value of Stock on Hand/Average Monthly Sales

- Healthy benchmark:

- Fashion: 1.5-2.0

- Supermarket: 1.0-1.2

- Electronics: 1.3-1.8

- Example: Stock value $400K, monthly sales $200K → Stock-to-Sales = 400,000/200,000 = 2.0. This ratio is at the upper limit of the fashion benchmark (1.5-2.0). While still acceptable, it suggests inventory levels are high relative to sales. Suppose you’re in such a case. You should monitor this closely and possibly implement promotional strategies if this trend continues to prevent excess inventory buildup.

5. Sell-Through Rate: Indicates the percentage of stock sold versus what you originally had.

- Formula: (Units Sold/Units Received) × 100%

- Healthy benchmark:

- Luxury fashion: 60-70%

- Fast fashion: 80-85%

- Supermarket: >90%

- Example: Fashion store receives 1000 units, sells 750 → Sell-through = (750/1000) × 100% = 75%. A sell-through rate of 75% is acceptable in luxury fashion, selling over 60-70%, but not good in fast fashion. If this is a fast-fashion retailer, it calls for a review of the pricing strategy or targeted promotions for the unsold units to achieve the optimal sell-through rate.

6. GMROI (Gross Margin Return on Inventory Investment): Tells how much profit you make for every dollar you spend on inventory.

- Formula: (Gross Profit/Average Inventory Value) × 100%

- Healthy benchmark: >200% considered good across most sectors

- Example: Gross profit $800K, average inventory $400K → GMROI = (800,000/400,000) × 100% = 200%. Most successful businesses aim for above 200% – so while this is okay, you might want to look for ways to boost it, like adjusting your prices or finding better deals from suppliers.

7. Shrinkage Rate: Calculates how much inventory you lose from theft, damage, or mistakes.

- Formula: (Value of Lost Inventory/Total Inventory Value) × 100%

- Healthy benchmark: <1.5% for well-managed retail operations

- Example: Lost inventory $15K, total inventory $1M → Shrinkage = (15,000/1,000,000) × 100% = 1.5%. This is actually at the edge of what’s considered acceptable – retailers will want to tighten up security and handling procedures to get this number down.

8. Order Cycle Time: The time taken to receive the goods after placing the order. Usually, a shorter time brings more satisfaction to customers.

- Formula: Average days between order placement and delivery

- Healthy benchmark:

- Local suppliers: 3-5 days

- International: 15-30 days

- Example: Orders typically received 4 days after placement → Order Cycle Time = 4 days. According to the benchmark, if you’re getting your local orders in 4 days, you’re doing fine, though you could try to speed things up a bit.

9. Backorder Rate: This indicates the percentage of orders your team couldn’t fulfill due to stock unavailability. A higher rate indicates a need for better inventory storage.

- Formula: (Number of Backordered Items/Total Number of Orders) × 100%

- Healthy benchmark: <5% for efficient operations

- Example: 50 backorders from 1000 total orders → Backorder Rate = (50/1000) × 100% = 5%. For us, 5% is in the danger zone, so you must keep this under 5%. If you’re hitting this number, it’s time to predict better what you’ll need and maybe keep a safer stock of popular items.

10. Carrying Cost of Inventory: Total cost of everything you spend to store and keep the inventory in good shape. It includes warehouse space, personnel, and insurance.

- Formula: (Storage + Insurance + Depreciation + Capital Costs)/Total Inventory Value

- Healthy benchmark: 15-30% of inventory value annually

- Example: Annual holding costs $60K, inventory value $400K → Carrying Cost = (60,000/400,000) × 100% = 15%. Compared to the benchmark, 15% is good. Most businesses spend 15-30% of their inventory value just keeping it around, so being at the low end means you’re running a tight ship.

11. Perfect Order Rate: Measures perfect deliveries – correct items, on time, no damage, proper paperwork.

- Formula: (Perfect Orders/Total Orders) × 100%

- Healthy benchmark: >95% for best-in-class operations

- Example: 950 perfect orders out of 1000 total → Perfect Order Rate = (950/1000) × 100% = 95%. The final rate meets the minimum standard for top performers, but there’s still room to do better. It’s worth looking at those 50 imperfect orders to see what went wrong.

12. Out-of-Stock Rate: This rate will tell you the frequency at which customers cannot purchase what they desire.

- Formula: (Number of Out-of-Stock SKUs/Total SKUs) × 100%

- Healthy benchmark:

- Supermarket: <5%

- Fashion: <10%

- Electronics: <8%

- Example: 40 out-of-stock SKUs from 1000 total → Out-of-stock rate = (40/1000) × 100% = 4%. If your store is in 4% for out-of-stock rate, you’re beating all those benchmarks.

13. Inventory Accuracy: It compares what’s on your shelves to what your computer says you have. Close matches mean your tracking system works effectively.

- Formula: (Physical Inventory Count/Recorded Inventory Count) × 100%

- Healthy benchmark: >98%

- Example: System shows 1000 units, physical count 985 → Inventory accuracy = (985/1000) × 100% = 98.5%. This is decent – anything above 98% is considered a good benchmark. However, those 15 missing items still need explaining, so keep doing regular counts and investigate any differences you find.

You might like: How to effortlessly track unit of measurement (UoM) inventory?

5 inventory analysis and forecasting methods

1. Quantitative forecasting

Quantitative forecasting uses past inventory and sales data to estimate future stock requirements.

For example, a retail store can look at sales of the last two years and predict the number of units of each product to buy for the next season. This approach is based on complex data such as previously achieved sales volume, out-of-stock occurrences, and seasonal peaks.

Source: Luru

2. Qualitative forecasting

Qualitative forecasting in retail combines expert opinion and market research with observations to fill in replenishment needs when data is insufficient.

For instance, managers may try to explain the stock shrinkage through insight like the following:

- Store personnel who observe customers regularly asking for things that are out of stock

- Trained buyers who are aware of fashion trends that may change the need for inventory levels

- Consumers who express their frustration about the items that they wish the store sells to help their family and themselves

- Modelling of changing tastes and needs of consumers over the long term relevant to stock requirements

This sort of approach is handy for new product launches or new geographical markets where history is non-existent.

Source: Hubspot

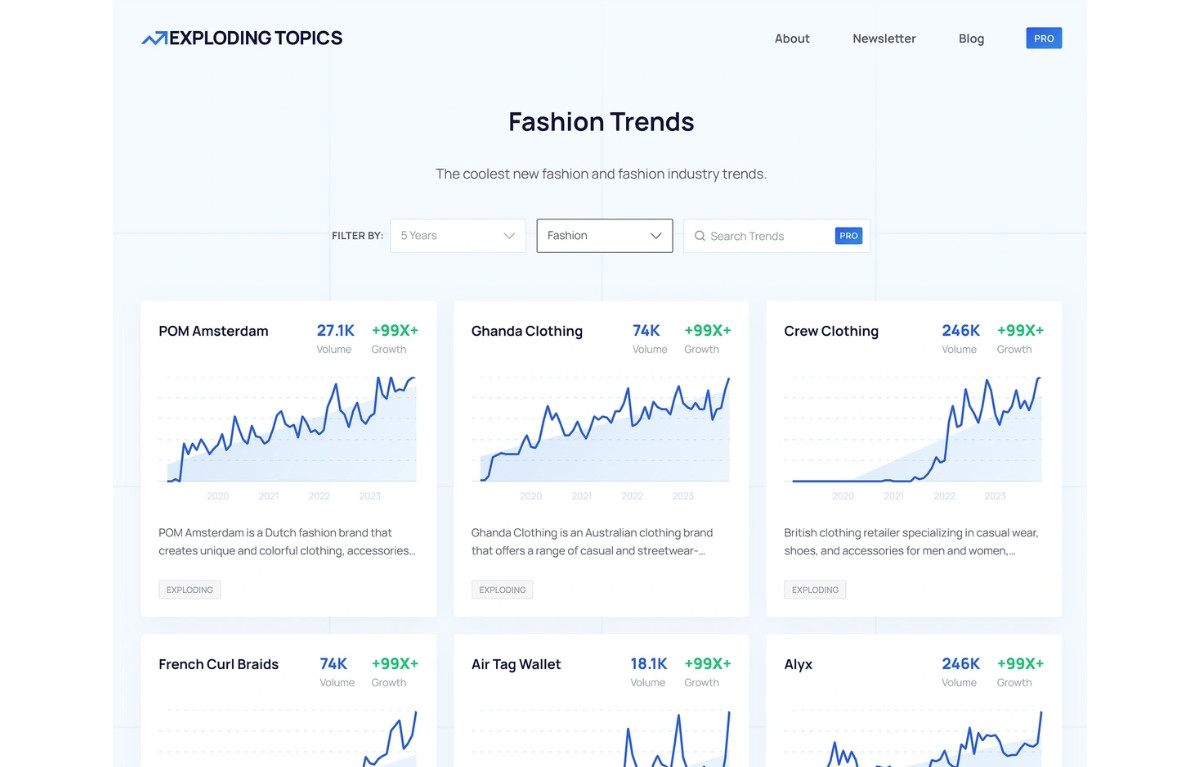

3. Trend forecasting

Trend forecasting is concerned with anticipating the products that will be in demand due to changes in the market and the behavior of consumers. It assists in determining the right assortment of goods at the right time. Besides, trend forecasting utilizes quantitative and time-series data, which refers to the numerical data elements that depict trends over various periods.

For instance, if a clothing retailer wants to know what engages people into buying clothes, social media, fashion show reports, and street stylists can help.

Source: Exploding Topics

4. Seasonal forecasting

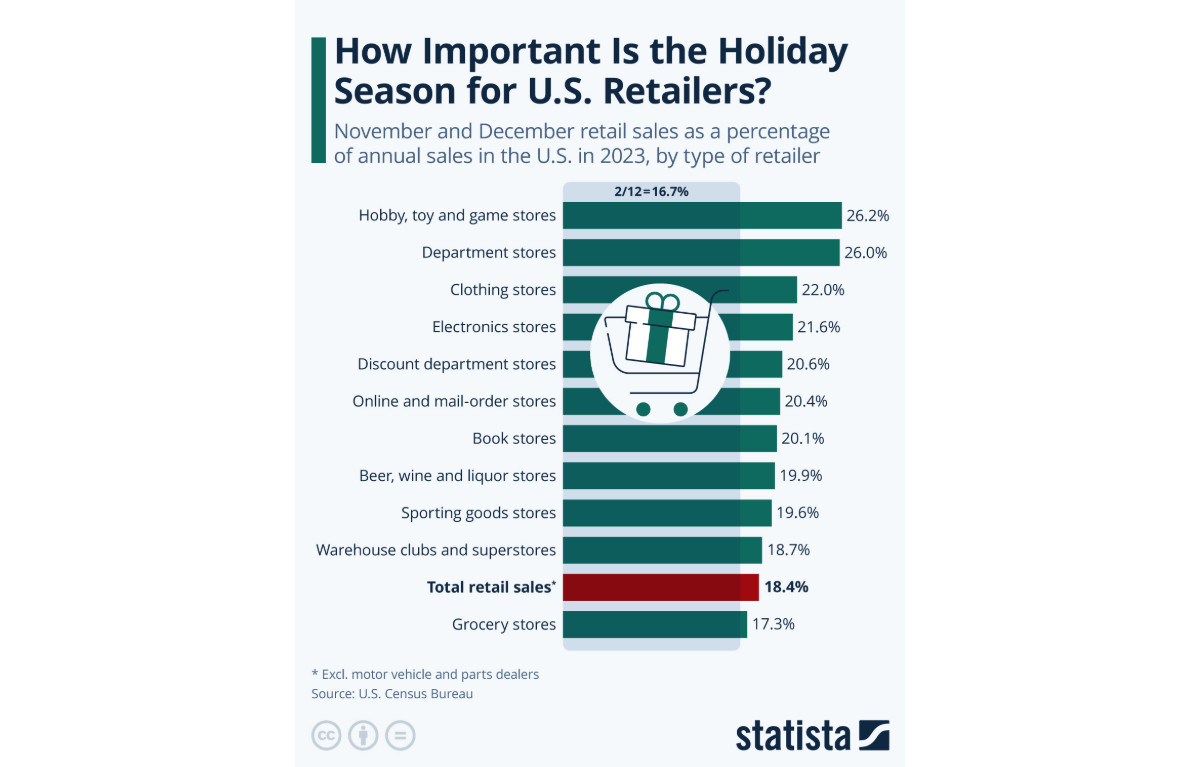

Seasonal forecasting is a famous key tool in retail inventory management. They allow the store to be ready for expected changes in demand throughout the year.

For example, a retail store analyzes past years’ data to decide when to raise the sale of school supplies, winter clothes, and holiday decorations, making for the appropriate school, fall/winter, and pre-holiday seasons. Seasonal forecasting ensures enough stock during busy times while preventing overstock during off-peak times.

Source: Statista

5. Graphical forecasting

For retail inventory managers, graphical forecasting transforms complex sales and stock data into visual formats that help identify patterns and make quick decisions.

While using graphical forecasting to assist inventory control, here are some forms of graphical representation that you may consider:

- Line graphs show sales trends over time, helping identify seasonal peaks

- Histograms display product movement patterns across different store locations

- Pie charts compare the sales performance of different product categories

- etc.

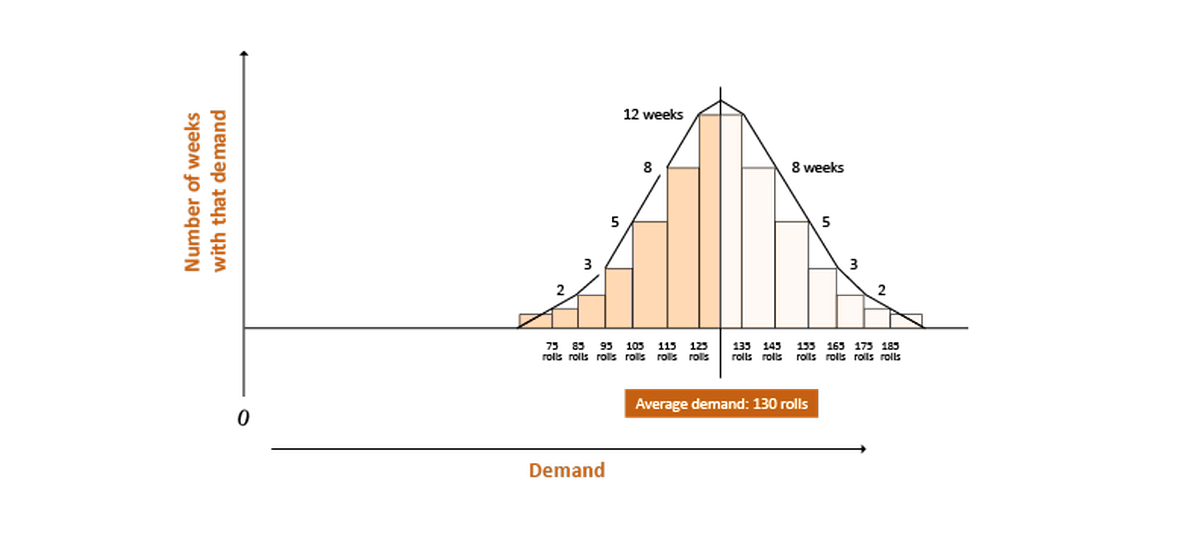

Example histogram showing weekly demand for paper rolls across 52 weeks — Source: ASCM

Top 5 inventory audit methods

1. Physical inventory counts (but modernized with mobile scanning devices)

Although this audit inventory method seems outdated, physical counting is still one of the most common methods of taking inventory. The goal is simple: to ensure that your system’s numbers match what is on your shelves. It involves several basic steps:

- Planning ahead

- Organizing your stock

- Counting everything

- Creating reports

Take a clothing store: Instead of closing for a whole weekend to count everything, they might count a few racks each day. If the computer says they have 50 blue t-shirts, but they only find 48, they need to figure out what happened to those missing shirts.

2. Cut off analysis

The cut-off analysis practice refers to stopping all activities related to procuring inventory and check-out transactions so that a manager can take the precise count. This ensures that the items consumed or acquired in a particular accounting period are accounted for to prevent over or under-recording.

With this method, auditors can reflect the actual value of the inventory in the system. Though it is disruptive to businesses, it helps them get an accurate value of the inventory they have at hand when conducting regular audits or reviews.

For example, a pharmacy takes a quick break on Monday morning to verify that all Sunday’s sales were accurately deducted from inventory before starting the new week’s transactions.

3. Random sampling

Random sampling is much faster than taking inventory. It involves checking a small sample of items in the inventory against their records to determine if those records are accurate. This process is much faster and more efficient than doing physical counts because it allows businesses to avoid the hassle of separately verifying each item in the inventory.

The techniques involve classifying the inventory, applying statistical methods to determine an optimal sample size, and ensuring that the sample represents most inventory segments.

For example, a supermarket might randomly count 50 items out of 5,000 products. If they find mistakes in 5 items, they may have similar issues with other products.

4. Cycle counting

Cycle counting is one of the best retail inventory management techniques to make sure their actual inventory matches what’s written in their records. Instead of counting everything at once, they count a few items at a time on a regular schedule. Eventually, they work their way through counting all their products.

Warehouse managers create plans for their staff to check these items. When done right, this process helps catch mistakes early, keeps inventory records accurate, and still lets workers focus on their daily tasks simultaneously.

For example, a bookstore splits the store into 20 sections and counts one section each Monday. Week 1, they count fiction books. In week 2, they counted children’s books and so on. They never have to close the store, and everything gets counted twice a year.

5. ABC analysis-based auditing

As mentioned above, in inventory ordering techniques, ABC analysis helps you sort your products according to their importance to your retail stores.

For example, an electronics store does it based on value:

- They count expensive stuff like phones and laptops every week

- Medium-priced items like cables get counted monthly

- Cheap items like phone cases get counted every three months

This way, retailers spend most of their time keeping track of valuable items while still keeping an eye on everything else.

Interested? Read more: Inventory audit: 9 procedures and optimization checklist

5 common challenges of retail inventory management

The key challenges in inventory management for retail businesses are carrying too much unsalable inventory, not having enough inventory to meet orders, and failing to manage inventory properly.

Other retail inventory management challenges include:

1. Poor real-time stock visibility

Running a store is tough when you don’t know exactly what products you have available. This gets even harder when you open more locations. Without a clear picture of your inventory across all stores, you might run out of popular items or order too much of others. This creates headaches like delayed restocking and upset customers.

Each store location has unique challenges – some products sell better in certain areas, and customer demand changes constantly. If you can’t keep track of these differences, you end up with too much stock in some places and not enough in others.

2. Inefficient demand forecasting

Many stores still use old-fashioned ways to guess what their customers will buy, like basic spreadsheets. This might work for a small shop, but it becomes a real problem when the business grows. These outdated methods can’t handle large amounts of data well, and teams often work with different numbers.

When everyone’s not on the same page, it leads to bad decisions – you either don’t have enough products to sell, or your warehouse is stuffed with items nobody wants.

3. Stock level imbalances

When stores buy too many products that customers aren’t really interested in, they face several problems.

- First, the warehouses become congested with goods that you can’t sell.

- Secondly, their money gets tied up in products just sitting there. Most of the time, these items expire or become obsolete before being sold. Both scenarios waste money and space.

Not having enough products is just as bad. When items run out, customers can’t buy what they want. This is especially bad when popular items run out during busy times like Christmas shopping.

Such poor retail store inventory management leads to frustrated customers and lost sales. Shoppers find getting out-of-stock messages, shipping delays, or order cancellations frustrating. Of course, they quickly switch stores.

4. Inefficient warehouse operations

For most retailers, keeping track of inventory and orders is hard enough when selling on one platform. Imagine the chaos tracking stock levels when selling on a Shopify store, plus Amazon, eBay, Etsy, and physical locations.

Not to mention, much research suggests that inventory opacity, inaccurate or lacking demand forecasts, and the absence of automation hinder multichannel fulfillment in several ways.

- 43% of retailers cite that lack of real-time inventory visibility as their biggest challenge in multichannel fulfillment

- Almost 49% of the companies do not have full visibility and control of their inventory across channels.

- Companies counting inventory by hand make 35% more mistakes than those using automated systems.

5. Manual process bottlenecks

Retail brands rely on inventory management workarounds, like using multiple stores to track inventory by location. But this increases your workload when you have to recreate, sync, or update inventory for each store.

Not to mention, manual inventory tracking using spreadsheets is based on fragmented information and cannot support cross-channel operations. It also denies inventory visibility needed during peak seasons or special events like flash sales.

While these inventory challenges are serious, remember that every problem has a solution.

4 best practices for retail inventory management

Here are several retail inventory management best practices you should put in place to ensure the efficiency and accuracy of your stores:

1. Project accurate sales numbers

The amount of stock you have on hand directly affects how much you plan to sell and how fast you plan.

Projections are tough for startups. Dig up all the information you can find online to create an estimated baseline, then adjust your expectations every 90 days based on actual data.

If you have a retail business already, use the sales data and growth forecasts to determine how much inventory you should keep on hand and when to reorder each item. Focus heavily on your best-selling products.

2. Appoint a warehouse manager

A warehouse manager supervises a warehouse’s day-to-day activities and ensures that all employees on the ground are updating software systems regularly and complying with company policies. This includes scanning products into and out of the right locations when they arrive, moving products from one place in the warehouse to another, and when they go out for delivery to a customer. The warehouse manager also ensures quality assurance checks and regular inventory audits are performed as planned.

3. Establish regular inventory cycle counts

While inventory sits in storage, it needs regular tracking of what is on hand. Companies could write off 2% to 10% of their products annually without a periodic cyclic inventory process due to loss or theft. Periodic auditing of inventories is necessary to keep the percentage of vanished goods as low as possible.

4. Implement a real-time tracking system

Retailers can track inventory manually, but nowadays, it is much better to use retail POS with inventory management software. Such advanced software can greatly assist you in automatically updating your inventory levels in real time by scanning items and locations throughout your storage facility.

What is the future of inventory management in retail?

New technological tools have made tracking and managing inventory much easier. The following are three great tools that are significantly altering the inventory retail management approaches of various organizations:

1. Artificial Intelligence (AI)

AI systems can increasingly autonomously make intelligent decisions regarding inventory. Such systems identify buying patterns and automatically adjust stock levels whenever customer demands fluctuate. These smart systems keep learning and evolving in their management of inventory.

2. Predictive Analytics

Predictive analytics is an advanced forecasting tool. It analyzes historical sales data and applies unique mathematical formulas to anticipate future requirements. As more data is supplied, the system gains insights into business patterns. This ultimately helps in making better decisions regarding stock levels and reorder timings.

3. Internet of Things (IoT)

IoT refers to the installation of small tracking devices on inventory items. These devices track the precise location of products at all times. This enables the staff to locate items quickly. It will always give you real-time information about your stock levels. Therefore, it efficiently manages your warehouse and helps you wisely decide regarding orders.

How can Magestore help?

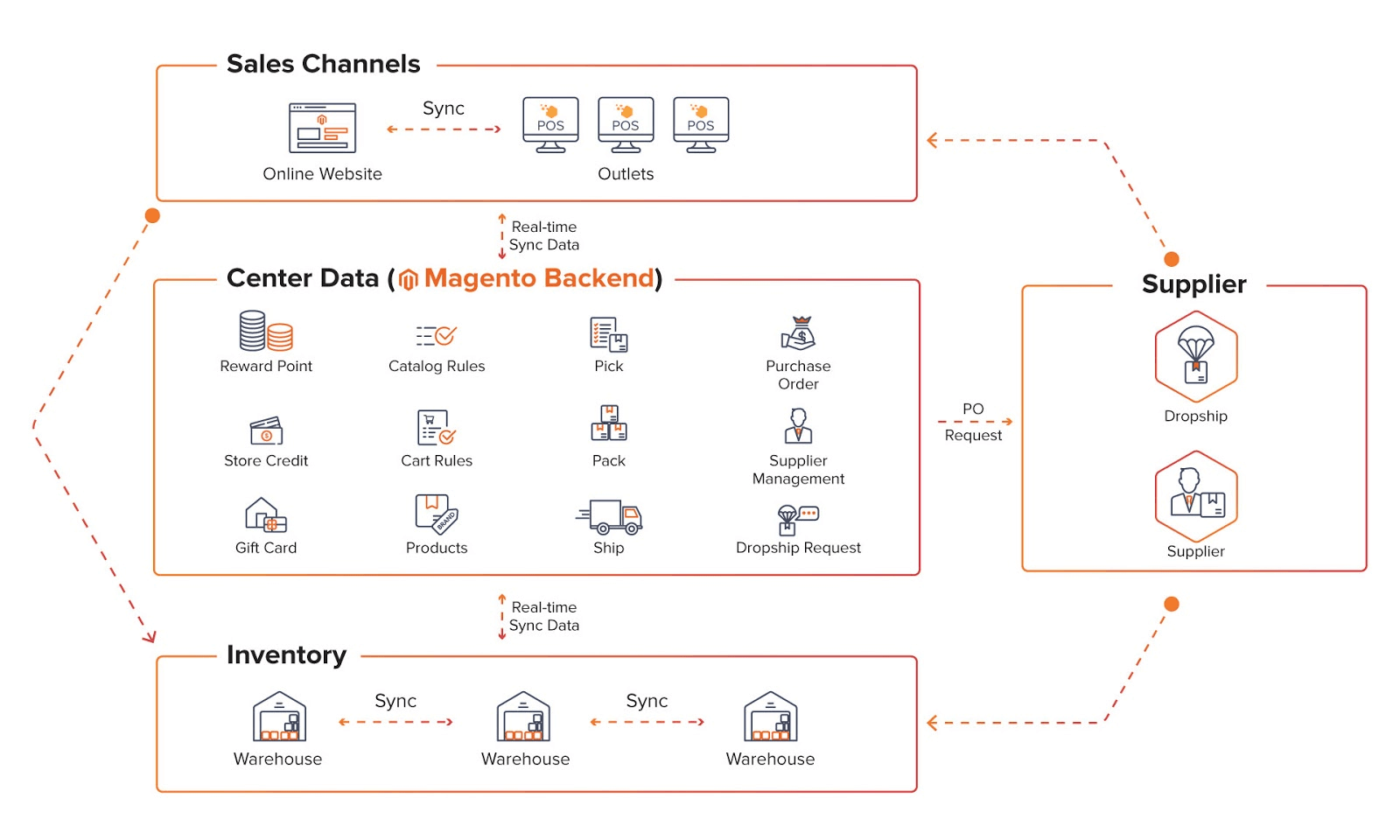

Managing multiple stores is a breeze with Magestore POS. There is no limit to the number of stores and warehouses retailers can set up. The movement of stocks at different locations is easy, and it ensures each location has just the right amount of products. Everything updates in real time, so your figures are always accurate.

Here’s what Magestore POS inventory can do for you:

1. Complete stock visibility across channels

Never worry about stock discrepancies again. The real-time inventory tracking system keeps your stock levels accurate across all locations – stores, warehouses, and online channels (Shopify and Magento). When items arrive at your loading bay or move between locations, a simple scan instantly updates your inventory counts.

For instance, in Magestore POS, if 10 items are delivered, you would scan them at the loading bay door. The system then updates to reflect that these 10 items are waiting to be picked up.

As employees move those items into Aisle 3, Bin 22, they check them in, and the system updates them automatically. Staff should do it every time someone moves a product. Then, the warehouse manager can look at the retail store software (RMS) to determine where everything is supposed to be and confirm that the information is accurate.

2. Smart inventory forecasting

Make better buying decisions with data-backed inventory forecasting. Magestore POS examines your historical sales data and seasonal patterns to:

- Accurately predict future demand

- Help set optimal reorder points

- Maintain ideal stock levels for each location

- Avoid stockouts of high-demand items

3. Less manual work, more getting things done

Stop counting everything by hand. The Magestore inventory management software automatically creates orders when supplies run low, helps you move products between stores, and makes counting inventory much easier. You’ll also get clear reports showing everything performs, saving work hours.

Whether you’re running two stores or twenty, we can make it simple to manage them all. You’ll have everything you need to keep costs down and ensure customers can always find what they want.

Conclusion

Retail inventory management 2025 will be much more than an exercise in product finding on shelves. The retail environment is evolving rapidly, and effective inventory management can provide a significant advantage over competitors, regardless of whether you operate a single store or ten.

What differentiates the successful stores from the struggling ones? It boils down to:

- Stock management fundamentals: knowing what you have in stock, what you need, and when to order. These are simple yet significant steps.

- Use sound POS systems to track everything. No guessing – use data to know what’s selling and not.

- If something works well, stick with it. Once you identify good practices, institutionalize them.

- Tracking your numbers. Monitor what matters to make informed decisions fast.

We understand that inventory management for retail business is a huge hassle, but with the right approach and tools, it can even become one of your greatest advantages.

How can we help you get rid of all those inventory headaches? Talk to us. Book a quick demo with Magestore, and we’ll show you how your shop can operate better.

FAQs

1. What is retail inventory control?

Inventory control in retail manages and arranges stock levels, locations, and movements within a retail operation. This encompasses monitoring inventory levels, managing reorder points, and making sure stock count is accurate.

2. What are the 4 main steps in inventory management?

The four main steps in retail shop inventory management are:

- Purchasing inventory

- Receiving and storing inventory

- Tracking inventory levels

- Analyzing inventory data

3. What are retail inventory costs?

Retail inventory costs include:

- Carrying costs (storage, insurance, depreciation)

- Ordering costs

- Stockout costs

- Shrinkage costs

4. What is a good inventory turnover rate for retail?

Retail businesses typically have a moderate inventory turnover speed – 2-4 times a year. However, it can be different for various industries and business types. Thus, while fashion retailers might focus on high turnover ratios, purveyors of luxury brands might operate at lower rates.

5. What is the difference between inventory management and warehouse management?

Inventory management monitors and controls stock quantities, whereas warehouse management represents the procedures for keeping, arranging, and moving materials inside a warehouse. Inventory management in retail industry deals with what you have. Warehouse management deals with where and how you store it.

Amazing write up! Thanks for this post