Add-on available

Technology advancement has made the global supply chains faster and better. Now retailers can sell a wider range of products and have more options to fulfill orders. Some have begun to offer products that are only purchased on the back of sales orders, called back to back order. Let’s explore the who, why, when, and how of this process.

What kind of businesses benefit from back to back order?

Many businesses use a combination of 2 inventory models:

- Buy-hold-sell: You buy goods from your supplier, hold them in your warehouse, then sell them to your customers.

- Sell-source-ship: You complete the sale with your customer, get the goods from the supplier, and ship them to the customer.

Back to back order is a common process for wholesalers or retailers that follow the sell-source-ship business model. Thanks to it retailers can tie customer demand with supply more closely and carry less inventory with relatively short lead times. Let’s look at these benefits next.

Back to back order benefits

Efficient order management

In back to back order, retailers will link a sales order with one or several purchase orders. The sales order and purchase order can be connected directly or via an order management system. Your staff can monitor any changes to the purchase orders and keep your customers updated.

When you receive goods from the suppliers, your warehouse staff will know exactly which order they belong to and begin shipping to your customers. You’ll ship all the items from one central location instead of shuffling stock between intermediate locations, reducing the time to handle goods.

Therefore, both your receiving and fulfilling processes are faster.

Besides, the items won’t be used for another order or demand by accident, keeping your inventory level accurate.

Lower inventory cost

With this method you don’t have to store everything you sell in your usual stock. You’ll benefit from lower costs of procuring and carrying items, especially if you sell high-value products.

Holding less inventory also means you’ll save warehouse spaces and rental fees. The moment your warehouse receives the goods, you can ship to the customer immediately.

Retailers can utilize the extra resources in many ways:

- Stock your fast selling products or items with longer lead times

- Repurpose your warehouse

- Redirect your funds towards other business operations such as curbside pickup or promotions

More sales opportunities

Retailers can expand your product catalog beyond what you have in stock and offer a more comprehensive range of items to your customers. You’ll be able to meet customer demand better and gain more sales.

When should retailers use back to back order?

Retailers can utilize this method to handle 3 common scenarios:

- Selling custom design goods. If you’re selling products specifically designed based on customer requests, you’ll want to order them from the supplier after the customer places the sales order.

- Ship products that you don’t want to stock. You may sell products that you don’t want to keep in your warehouses due to:

- Slow sales velocity

- High procurement cost

- Space limitations

- Specific storage or climate requirements

- Process orders that you don’t have enough in stock. For example, the customer places a large order that exceeds the goods you can ship even if you deplete your inventory. Another situation is that some items have already been reserved for another order. In both cases, if the customer’s willing to wait for the whole order, you can purchase the entire quantity from your supplier and ship them later.

Next, let’s explore the process in more detail.

Back to back order flow

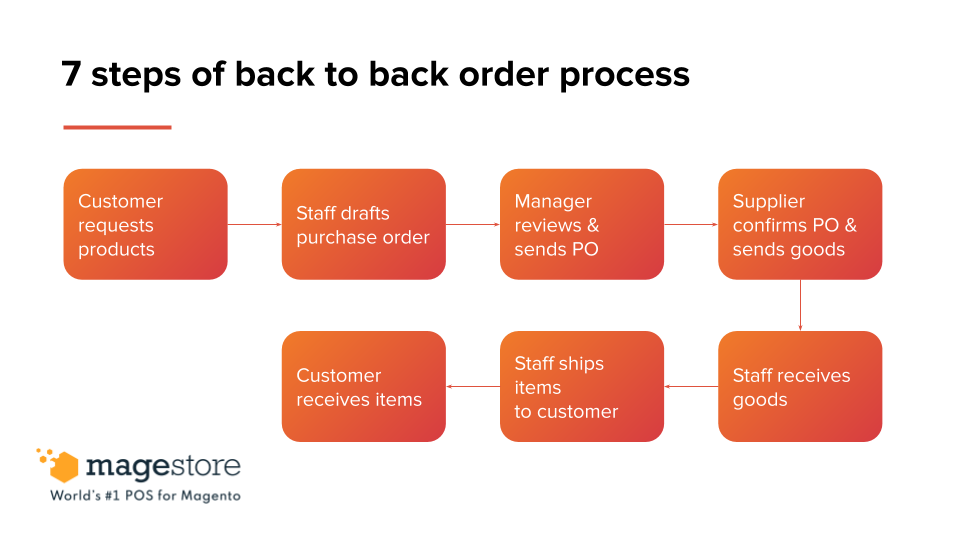

The back to back order process includes 7 key steps.

- Customer requests products. The customer places an order with items that aren’t in stock. Many retail systems will mark these products as backorder items.

- Staff drafts purchase order. Your staff will check the sales order, and prepare a purchase order for the backorder items.

- Manager reviews and sends PO. Your warehouse or finance manager will approve the PO and send the requests to the supplier. The PO should include the details of the original SO and vice versa.

- Supplier confirms PO and sends goods. Your supplier will confirm if they can fulfill the PO. Then they’ll prepare and send the goods to your destination warehouse. Your PO system should update the status of both the PO and SO.

- Staff receives goods. Your employee can accept the items and complete the PO. Your order fulfillment system should mark the backorder items as ready to ship.

- Staff ships items to customer. In this step, your warehouse staff will ship the backorder items to the customer and update the SO’s status.

- Customer receives items. When the customer receives the items and pays any remaining fees, the SO is complete.

Throughout this process, any changes to the PO’s status should reflect on the SO as well. Using a centralized order management system can help automate the process and keep your staff updated.

Last words

Back to back order creates more sales opportunities for retailers while keeping minimum inventory. There’s less pressure on stocking goods and more emphasis on meeting customer needs.

To implement this process successfully, you’ll need strong connections in your supply chain. Besides, it’s necessary to have a centralized system covering purchasing, order management, inventory, and sales.

If you’re a Magento merchant looking to optimize your fulfillment process, you can talk to our retail expert for a free consultation. Together we can build the best-fit solution for your business.