Today’s retailers need accurate demand forecasts for every SKU in all stores to optimize inventory management and maximize ROI. But applying this level of stock control requires a big data analytics approach which is designed for the digital era of retailing.

This article will help you understand what inventory forecasting actually is, the most common methods of demand forecasting in retail, and how to take full advantage of this technology for your online-offline business.

Whether you run an online store or operate a physical retail store, inventory forecasting helps you:

- Fulfill customer orders right away for a better customer experience

- Optimize inventory investments — storage space, staff, and budget — in an optimal way

- Always be prepared for an increase in product demand

- Achieve financial goals in a hassle-free and predictable way

If you overstock products, your cash flow will be tied up in unsold items while you have to pay for other inventory costs. Similarly, if you’re unable to maintain sufficient inventory levels, you may lose potential sales.

The solution here is to find the right balance between cash flow management and optimizing inventory levels. That is where inventory forecasting does the job.

In this post, we’ll explain what inventory forecasting is and why it’s essential to help you make better decisions at purchasing.

What is inventory demand forecasting?

Inventory forecasting in retail is the act of making an informed projection on how much stock will be purchased from suppliers to satisfy demand over a given time period.

As a retailer, you can leverage a system or labor resources to measure and maintain stock levels based on historical data. Besides, the forecasting also involves future promotional campaigns and various external factors – to accurately predict when and what to purchase next.

Basically, inventory forecasting needs you to set forecast boundaries within a time frame and a clear starting point to work on. Then you can combine them with trends and other factors such as:

- Sales velocity

- Marketing activity

- Seasonality

- Unexpected publicity

- Industry-specific effects

Why the need for inventory forecasting?

Here are some of the key benefits of inventory forecasting that makes you want to apply to your online-to-offline business:

Less inventory storage space

Forecasting the inventory demand can minimize costs related to acquiring storage space. If you store a large volume of products for a long time in a warehouse, they’ll stay there without bringing in any money. That’s why you need to estimate how much inventory you need for a known time period. That way you can:

- improve inventory levels

- maximize your cash flow

- have more resources to invest in other important aspects of driving sales such as marketing

Fewer stockouts

With inventory forecasting, you don’t need to worry about running out of stock since you always have enough stock to fulfill customer orders. In other words, you’ll be able to minimize lead time.

Less manual work, more automation

More predictions mean you can quickly adapt to changing demands. Inventory forecasting allows you to predict human resource needs better and automate the reordering process. As a result, you’ll reduce inventory holding costs and always have a better idea of what’s coming your way.

Better product cycles

Accurate inventory forecasting allows you to better manage inventory throughout the supply chain. You can improve productivity and better understand product cycles by knowing:

- the supplier or manufacturer’s lead times

- your warehousing facility’s receiving schedules

- the exact inventory levels you’ll need of each item to place a new purchase order

Utilizing inventory forecasting eliminates guesswork and lets you optimize production timelines and shipments.

Now that we have a better understanding of inventory forecasting let’s take a closer look at how you can forecast inventory and what is the process that your business should apply.

How to forecast inventory

There’s a lot of factors that contribute to effective inventory forecasting. If you are looking for a solution that can do all the hard work of forecasting and automated reordering, let’s dig deeper into the criteria you need to consider.

Set a forecast period

To calculate the inventory levels and order accurately, you need to select the right duration for your business. Focus on these 2 numbers:

- Your manufacturer or supplier’s production cycles

- Your inventory turnover rate

For example, if you sell out your inventory quickly, you’ll be able to repurchase and restock new inventory more frequently. So, a fashion retailer that sells apparel might have a smaller forecast period as compared to a business that sells furniture or expensive electronics.

With a customizable inventory forecasting system, you can easily change the time period based on your own business requirements, whether it’s 1 year, 90 days, or 30 days.

Study seasonal and buying trends

How does a system conduct predictive analytics on buying trends? Based on seasonal sales numbers, the forecasting system will collect historical data and detect changes in product demand over a specific time period.

For example, a retailer selling sports gear may see sales rise in the summer months. The system can then forecast this information to suggest increasing the inventory levels in the weeks leading up to summer and slowing down as the season comes to an end.

In order to do this, your system needs to centralize data in all sales channels. Then you can have a correct forecasting number of sales from online to offline stores. An omnichannel solution with strong inventory management and forecasting can help you achieve this.

Determine your reorder point

Each time you successfully fulfill a customer order, your inventory quantity decreases. And when it reaches a certain threshold, it will have to be restocked. The reorder point here is the number at which you have to send a new purchase order to the manufacturer.

Normally, a good forecasting solution will include low stock notifications via email or right in the backend system. You can create or edit low stock notification rules, and even better, you can set the next actions after receiving the notification.

Based on each business requirements and how complicated the rules have to be, the reorder point can be calculated by adding these key factors:

- Stock delivery lead time from the manufacturer to your warehouse. During the lead time, new order because you only have adequate stock for

- Your warehouse facility’s turnaround time when receiving stock

- The number of safety stock days if there’s a sudden rise in order demands or if delays happen on the manufacturer’s end

The total of above mentioned days will be multiplied by your average stock demand per day to give you the reorder point. Once an SKU’s inventory level reaches this reorder point, your system should send a notification to inform you that it’s time to generate a purchase order.

Calculate lead time and safety stock

Lead time is the time between placing a purchase order and when you receive the stock at your warehouse. Knowing this number will help you ensure that you have adequate supply during this time. Lead time demand is the estimated level of sales that happen during a purchase order’s lead time. For example, it will be the number of completed orders from the day you send a purchase request to when the purchase order arrives.

Here’s the formula for calculating your lead time demand:

Lead Time Demand = Lead Time (Days) * Predicted Daily Number of Sales

Safety stock prevents your business from going out-of-stock before you can restock it. If you’re low on inventory, you won’t be able to fulfill customer orders. Backordering works here, but you wouldn’t want to risk losing out on sales and customer loyalty. Maintaining safety stock levels allows you to meet orders promptly.

Here’s how you can measure safety stock:

Safety stock = (Maximum daily usage * Maximum lead time in days) – (Average daily usage * Average lead time in days).

A good forecasting software will calculate this for you. Make sure when you look for a solution, get a consultation from retail experts about the methodology to know the logic behind it.

Inventory forecasting models and techniques

Let’s take a look at some of the commonly used inventory forecasting models and techniques.

Quantitative forecasting

Quantitative forecasting uses historical sales data to predict future sales. The longer the retail company has been in business, the more accurate the forecasting will be. You’ll need at least a year’s worth of data. That is the minimum amount of data needed to identify seasonal trends. A dataset collected in many years will give you more precise estimations and insights into sales aspects.

Qualitative forecasting

Qualitative forecasting relies less on the data from your customer’s order history and more on external factors such as environmental forces, market intelligence, and economic demand. Because this is a specialized form of inventory forecasting, it shouldn’t be done by someone who lacks experience or by a simple forecasting system.

Inventory forecasting tools

If you fulfill orders yourself instead of using a third party, you should prepare for an inventory management solution that comes with forecasting tools. It will allow you to:

- Track your inventory levels and the number of items sold per day

- Generate reports to find which products sell more frequently

- Develop a better understanding of your company’s performance

- Help you develop other automation using business intelligence

Some inventory forecasting tools also enable you to visualize data, run inventory reports on sales and inventory metrics, and even offer you automated reorderings. It not only shows you which products and when you need to restock in the future, but also lets you assign warehouses and complete the purchase order with the supplier. This way, you can handle the order fulfillment a lot easier and faster.

How to forecast demand in Magento?

Demand forecasting or inventory forecasting isn’t a default feature of Magento. However, retailers can refer to Magestore’s retail management solution to fully track and easily automate the inventory replenishment. We’ll discover how to set up demand forecasting in the following.

Update threshold in Magento

Threshold in warehouse management is the minimum stock of an item retailers should keep in hand. When the stock is under the threshold quantity, it should be replenished to maintain the operation and prevent interruptions.

To calculate the number of items to be purchased, you’ll need to set up the threshold level first.

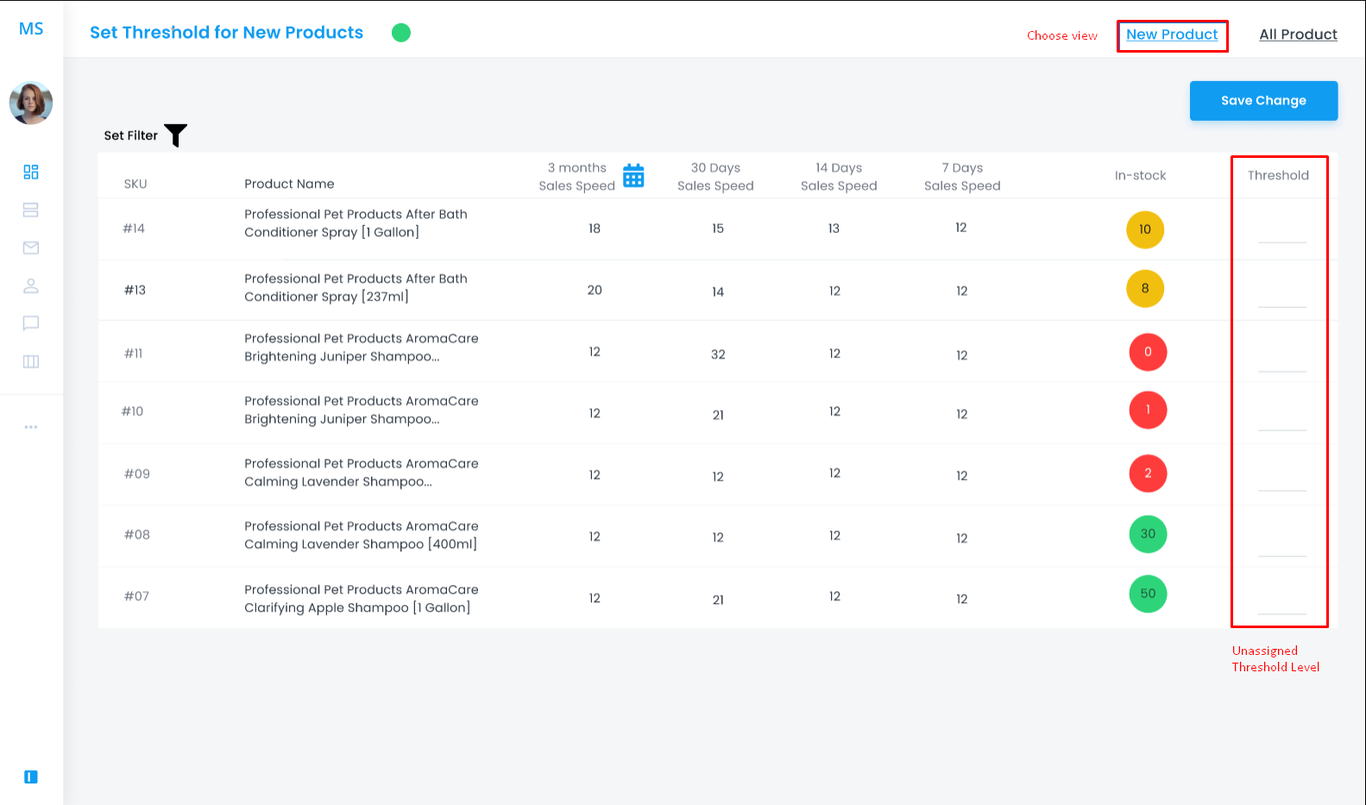

Go to the New Product view to enter the threshold level for each product. At this view, you can see all items needed to have a threshold level. After filling out the threshold for each product, all the assigned items will be moved to the All Product view.

New Product view

All Product view

Calculate the product sales speed

At this step, you can calculate product quantity to alert, purchase, or request based on the sales history.

There will be four columns calculating the average sales speed in different periods. The last three columns have been predefined: 30 days, 14 days, and 7 days, while the first column can be adjusted to fit your demands, which can be a period of time or a specific day in the past.

To input the time range to see statistics, click on the calendar icon.

You can input directly the From and To date, or choose the date on the calendar, a day, or a range of days.

If there are too many items, you can apply a filter to find the product easily.

Now in the filter interface, you can search the items based on their Barcode, SKU, Category, Brand, and Supplier. After defining the product sales speed, click Save Change.

From now on, the system will automatically calculate the sales speed which you can use for purchasing tasks later.

Key takeaways

Inventory forecasting can be complicated works if retailers do it manually without support from a professional system. Imagine how much time and money you have to put into a single forecasting time period if you don’t own data in a centralized place.

Don’t let the abundant jobs that can be done by technology stress you out. If you’re a Magento merchant looking to build inventory forecasting into your business, you can book a free consultation with our retail experts to save time. We’ll work together to build a tailor-made demand forecasting solution for your business.